Room in room design

Good design takes a step back! This statement is absolutely true for room-in-room systems as part of a holistic interior design. Ultimately, it is the entire interior that should convey the message of a modern, agile office and the message is about communication as well as effective and transparent processes. Do “dark boxes with dim lighting” fit in with this? From our point of view, no!

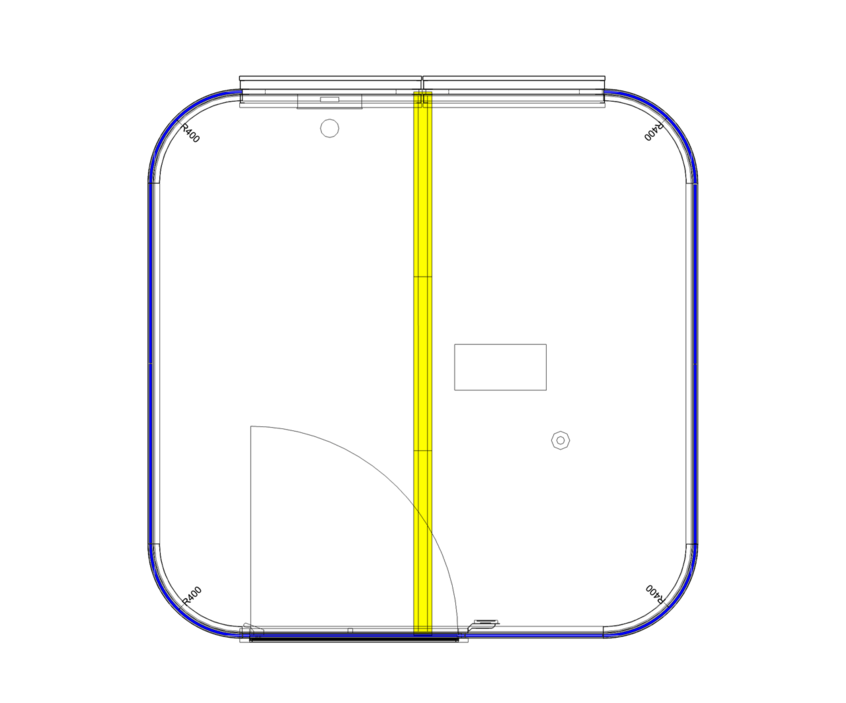

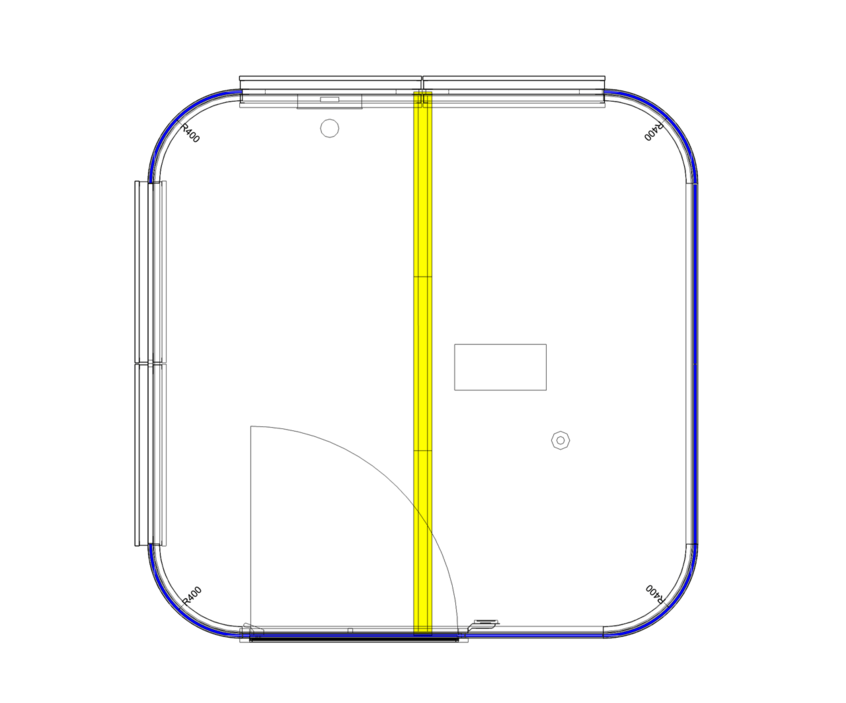

We love large, frameless glass surfaces and glass, support-free corners. In addition, curved glass can create special effects in the room. The frameless glass surfaces contribute to the light and timeless appearance of the vetroCUBE room-in-room system. This creates the necessary “width”, especially for small room units. The more comfortable, wide feeling of space is ultimately the prerequisite for the acceptance of this system. Viewed from the outside, the transparency offers exciting perspectives across the entire office space. This is particularly important when you consider the number of room-in-room units required in a fire protection section. In our experience, this is approximately one unit for 15 workstations. That's 2 to 3 units for a 400 m² area.

Nevertheless, the glass surfaces can be designed with foil decorations or closed off with curtains if desired. The discretion in the vetroCUBE can be adapted as required by partial foiling and changed at any time. In contrast to opaque wall elements, there is much greater flexibility here.

Two sound insulation classes: 37 dB and 40 dB

The room-in-room system vetroCUBE is available in two sound insulation classes. The proven 37 dB variant comes with 12 mm VSG glazing and already offers excellent sound insulation when installed. For special situations, we have supplemented the system with a 40 dB variant. Here we install 16 mm VSG panes for the glass surfaces. In addition, the solid wall elements, the ceiling and the door were modified accordingly, so that increased sound insulation is guaranteed when assembled.

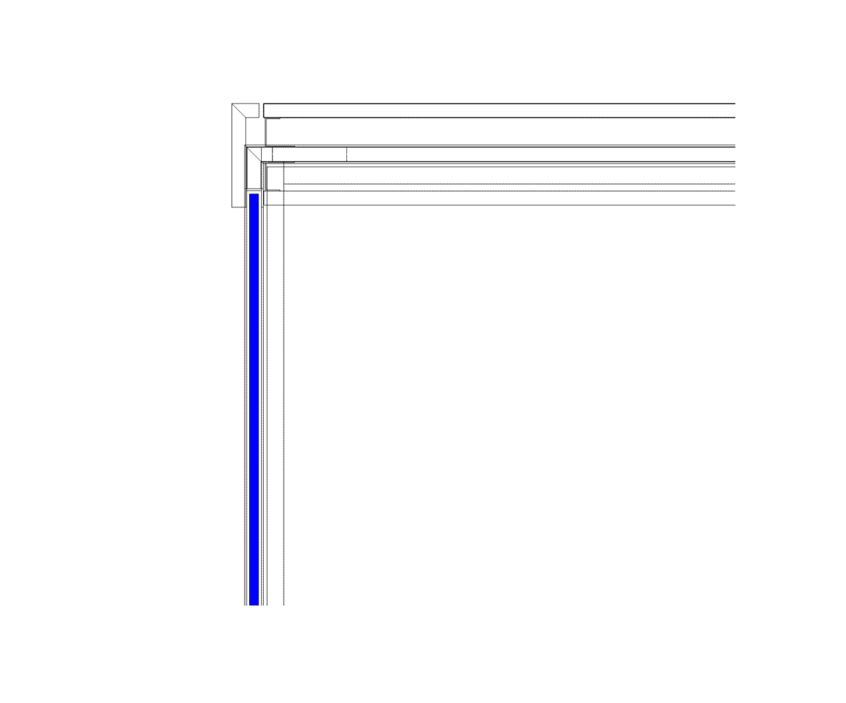

Sound insulation class 37 dB:

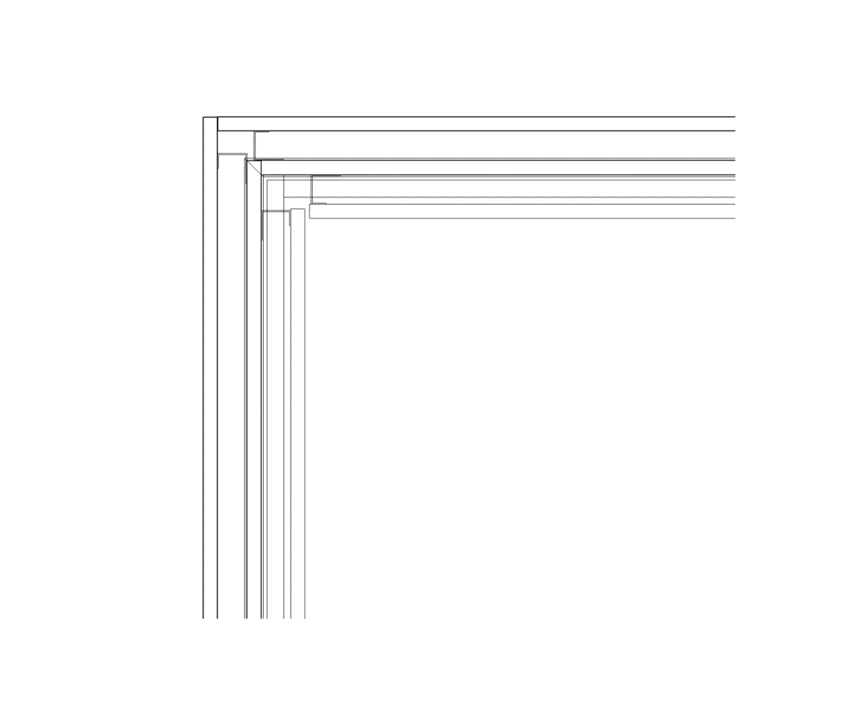

Sound insulation class 40 dB:

- EVERY size and every design available

- Sound insulation R´w 37 dB with 12 mm glazing

- Sound insulation R´w 40 dB with 16 mm glazing

- Hinged door or sliding door of your choice

- Ventilation at least 60 m³ per person per hour

- Ventilation thermally optimized

- Fan noise less than 30 dB

- Barrier-free, no step in the entrance

- Maintenance-free, no follow-up costs

- Acoustics can be adjusted as required

- Full wall function: absorber, decor, whiteboard

- Adaptation to the fire protection concept

- System floor as an option

- Solid wall instead of glass corners as an option

- Profiles anodized or RAL

- Surfaces RAL, decor or fabric

- Glasses clear, foiled or printed

- Sustainable manufacturing in Germany

Room-in-room door systems

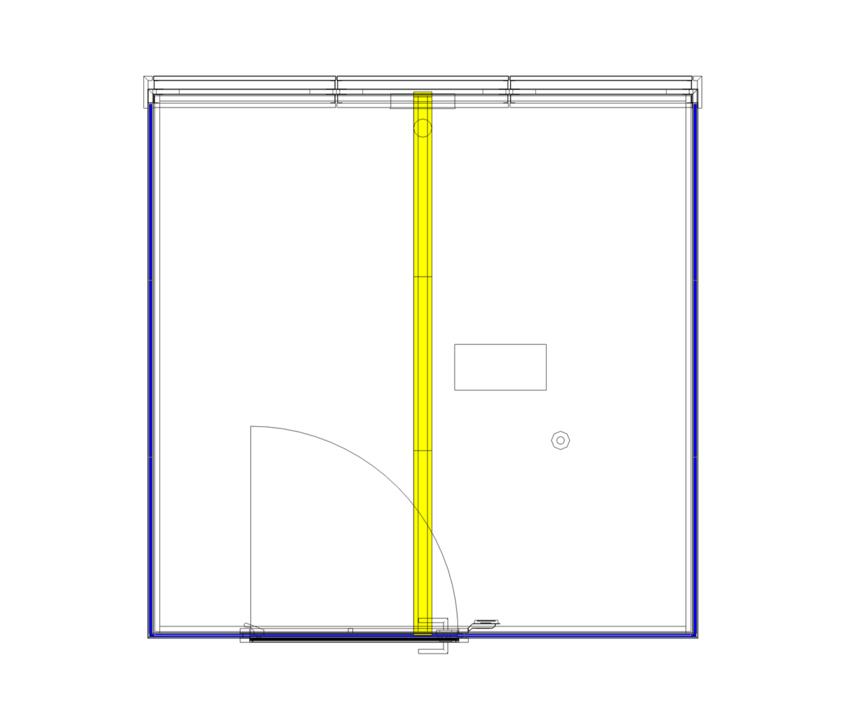

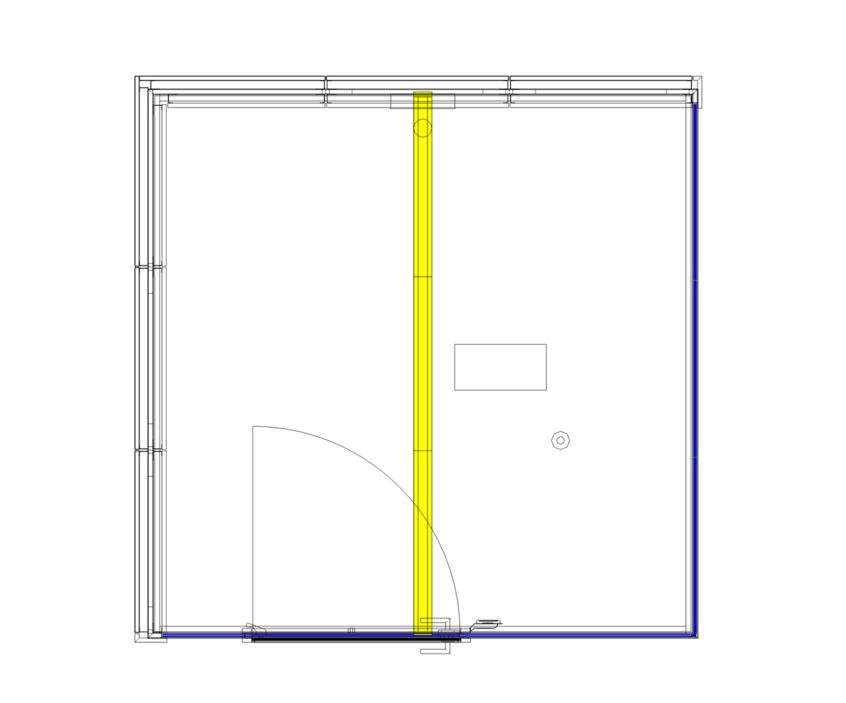

The standard door is the all-glass wing door with a lowerable bottom seal. A soundproof all-glass sliding door is also available. The sliding door system is a problem solver for tight spaces. With the sliding door, the room-in-room system still achieves a good 34 dB. This is made possible by mechanically or magnetically lifting seals on all sides. For the 40 dB variant, we preferably offer a solid, rebated wing door or a glass door in a rebated aluminum frame.

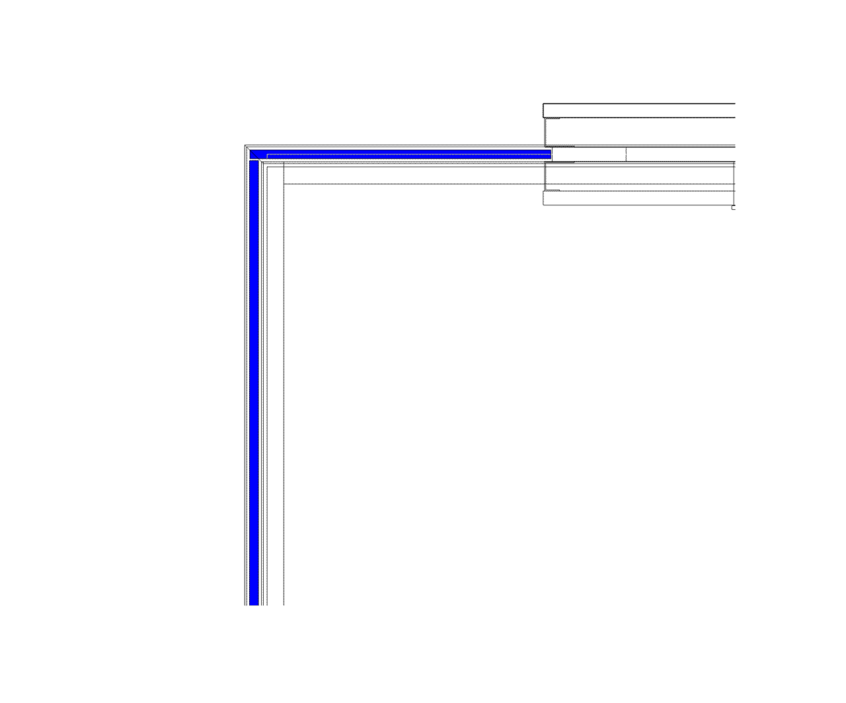

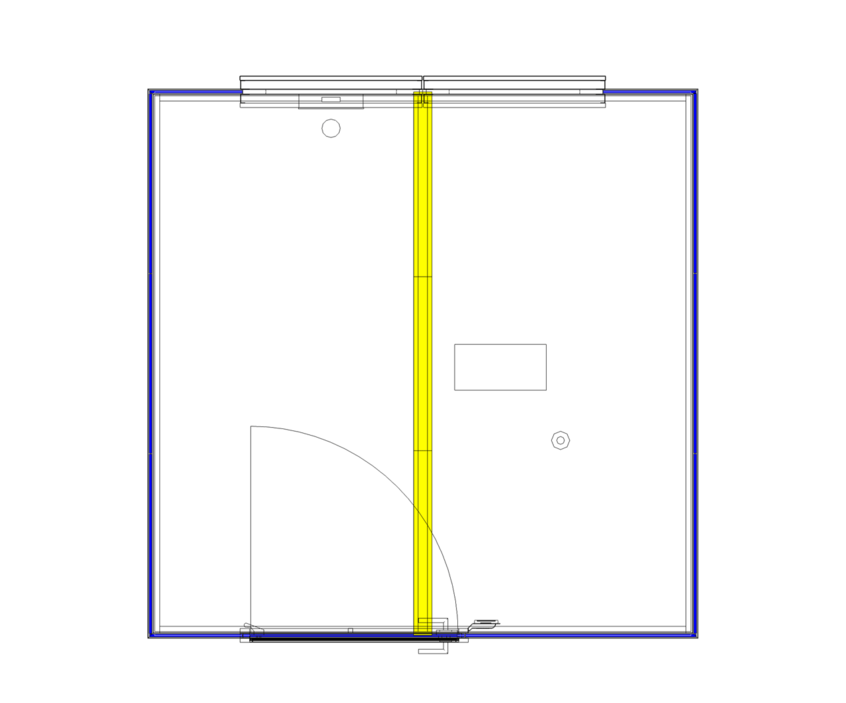

vetroCUBE with wing door:

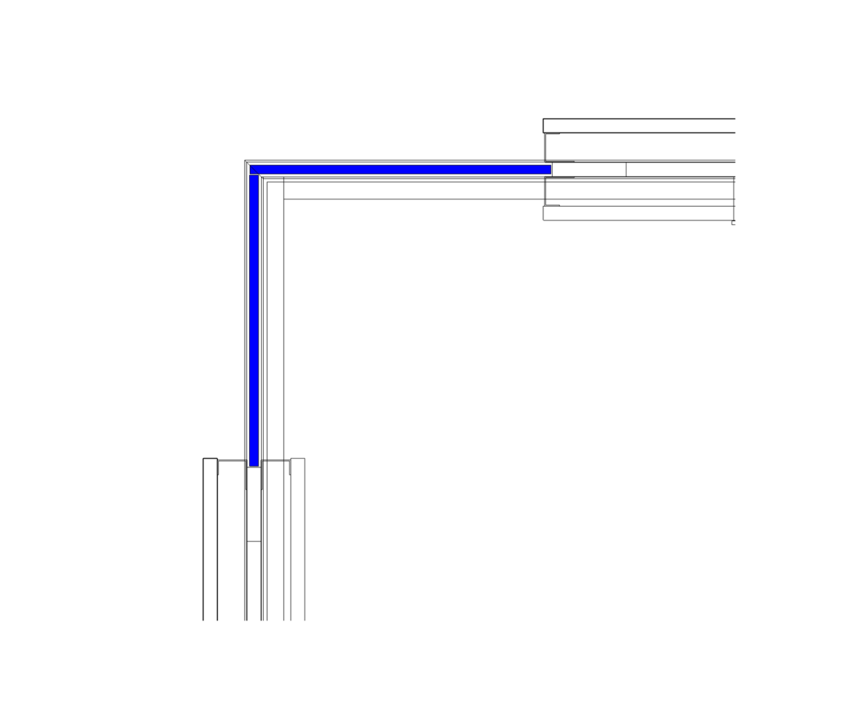

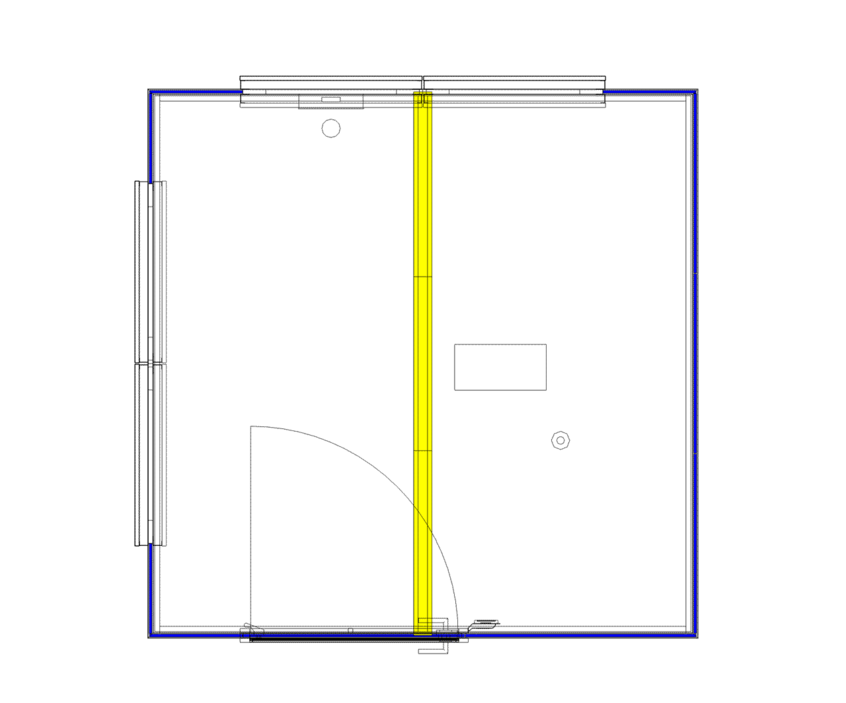

vetroCUBE with sliding door:

Room-in-room features:

vetroCUBE is highly flexible in size and design, so that available space can be optimally used and the design can be tailored to suit.

The room-in-room system is free-standing, soundproof, barrier-free and self-sufficient, i.e. independent of the building. It does not have to be attached to the floor, does not connect to the facade, wall or ceiling and does not require access to the window. The room-in-room system is ventilated, electrified and illuminated. On request, vetroCUBE can be equipped with comfortable, draft-free cooling and a cooling ceiling. The room-in-room unit is flexible, convertible and modular. It is adapted to the respective fire protection concept and, if desired, has an interface to the building management system. vetroCUBE is maintenance-free and can be converted or modularly changed at any time.

vetroCUBE, room in room Special features:

Outstanding features include the very good and certified sound insulation, the effective, quiet and controllable ventilation system, the maintenance-free nature of the vetroCUBE and the intelligent electrification and control with an interface to digital building management systems.

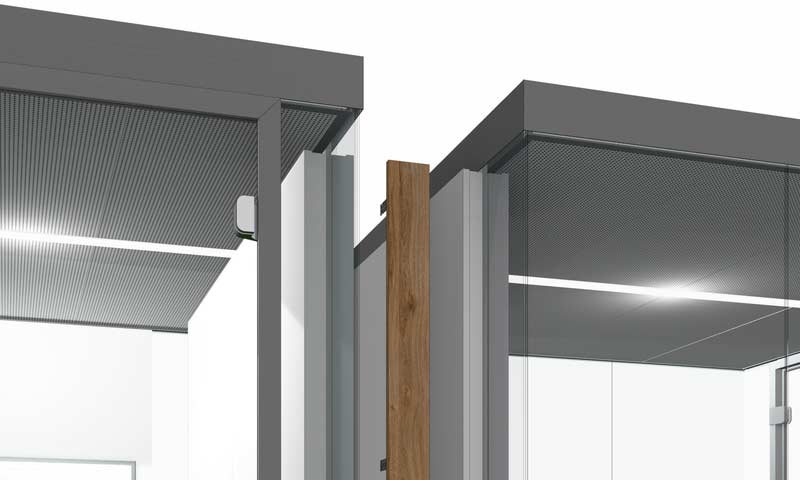

The design of the room-in-room construction is characterized by the frameless glass surfaces and the glass corners without supports. This technique leads to filigree, little space-consuming constructions. To the outside observer, vetroCUBE appears light, transparent and flooded with light. The appearance of the open office space is not disturbed. On the other hand, even very compact rooms appear spacious from the inside. The glass surfaces are not perceived as a boundary, so that the user has a pleasant feeling of space in the cube. This ultimately manifests the acceptance of the system.

Design options for the corners of the room-in-room:

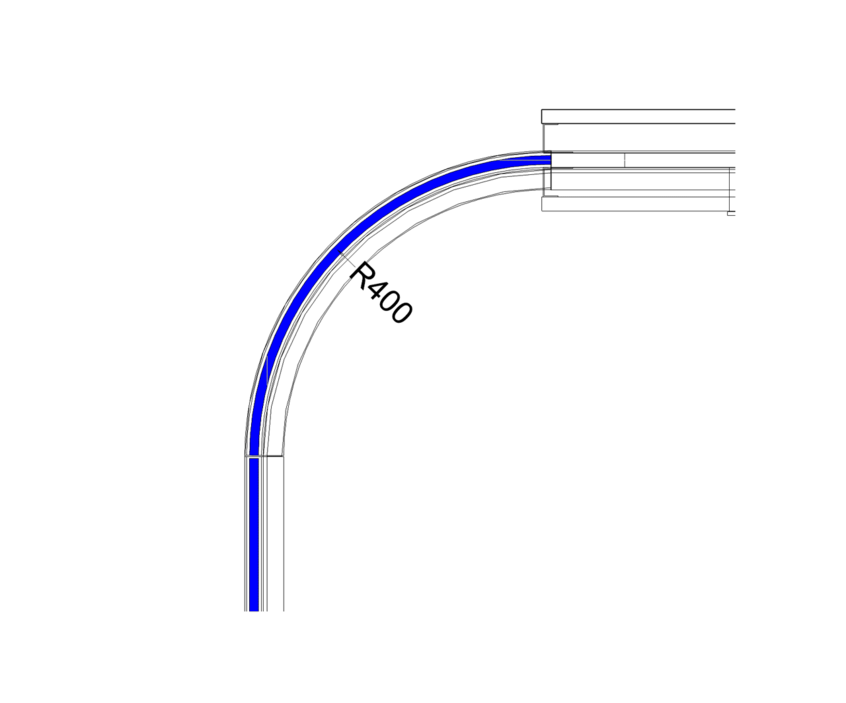

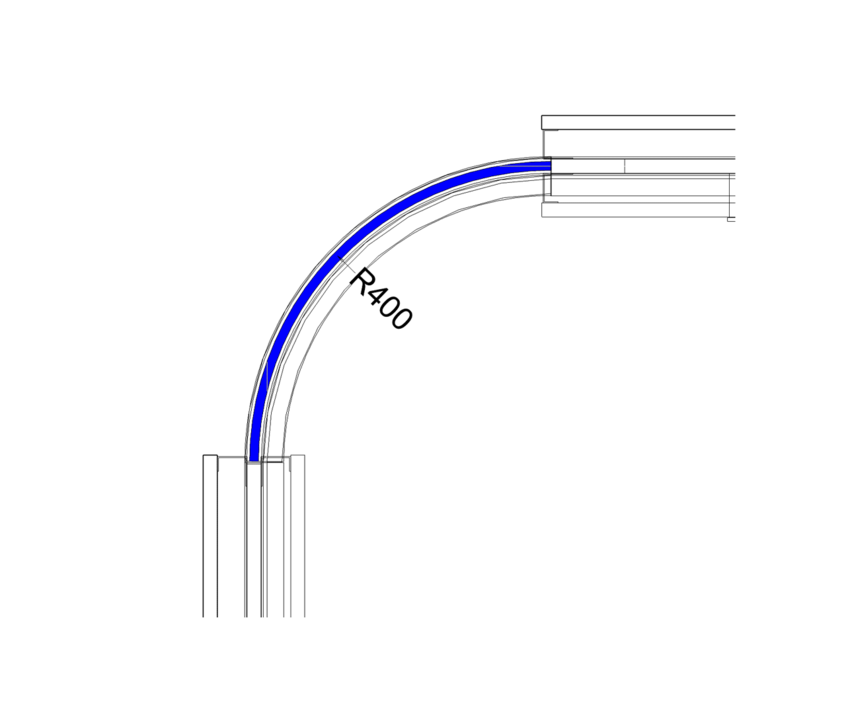

The design of the corners of the room-in-room units have a decisive influence on the design of the rooms. When introducing the vetroCUBE system, we decided to design the corner connection as a transparent, support-free glass-glass construction. Shortly afterwards we introduced the glass rotunda as a high-quality alternative. These details are crucial for the light and understated architecture of the room-in-room system. The transparent corners visually break up the construction, enable the planning of the smallest rooms and still give the user a spacious impression. The solution is very well received by architects. However, there are situations that require opaque corner connections. For this we offer “solid wall corners” or “glass solid wall corners”. The following matrix illustrates the possible variants. A vetroCUBE can certainly be designed with different corner solutions. Depending on the location, this may be necessary.

Possible uses of these room-in-room solutions:

No modern office without room-in-room systems!

Open office spaces, such as those necessary for hybrid working and agile working, need retreat spaces. These quiet areas are the backbone of an office based on the new work or smart office principle. As a thinker's cell, think tank, focus room, silent room, co-working, library, technology cube, whatever function you want to use in these retreat spaces, the room-in-room solutions are located in the middle zone, away from the facade. This area is not suitable for workplaces, but it offers exactly the space you need to offer the spatial diversity you want. This diversity makes your office agile. This diversity brings your teams together again and again and this diversity supports the transfer of know-how and thus the integration of new colleagues. Know-how stays in the company instead of retiring with the older knowledge holders.

Conservative interior design tools do not offer a solution. Partitions can rarely be installed in the middle zone. There is almost always no possibility of connecting these trapped rooms to the ventilation. Apart from that, floor-to-ceiling walls require a complex package of services from an architect. The lighting, electrification, ventilation, drywall bulkhead, fire protection and wall systems must be coordinated with every spatial change. This is exactly what the free-standing, independent, self-ventilating and adaptable room-in-room system was developed for.

Room-in-room systems can be located anywhere. You do not need a connection to the building or its infrastructure. This allows the interior design of existing buildings to be completely reinterpreted. These cubes provide retreat areas in the immediate vicinity of the workplace. Largely glazed, they are very easy to see and can therefore be used ad hoc. This creates spatial diversity, supports the change between communication and concentration and thus optimizes the processes in the company. The room-in-room system vetroCUBE becomes the “back bone” of a modern office space

When factory halls become offices ...

vetroCUBE supports the architect in the conversion of industrial wasteland or historic buildings for the office.

History and building concept as an example: A new utilisation concept is needed for a listed factory building built at the beginning of the 19th century. The building was revitalised and brought up to the latest fire protection standards. The historic façade was preserved.

Banks, advisory rooms in the banking hall

Banks benefit greatly from room-in-room construction. Cash desk halls can be expanded to include discreet consultation rooms quickly and without major disruption to operations. Banks must serve their customers personally and confidentially. There are opportunities here to optimize the business without any construction effort. Consultant rooms no longer necessarily have to be located on the facade or wall. Room-forming walls do not have to be pulled up to the ceiling, which is often designed, in order to be laboriously connected there. Free-standing room systems can be distributed in the checkout hall as necessary in order to offer the necessary services directly at the point of sale.

This also makes ‘loft style’ buildings interesting for office use. With intelligent conversion, these buildings in particular have enormous potential for modern office space. vetroCUBE, the self-supporting and self-sufficient room-in-room system from woodtec, helps planners to realise the necessary retreat areas independently of the building structure.

Banks, advisory rooms in the banking hall

Banks benefit greatly from room-in-room construction. Cash desk halls can be expanded to include discreet consultation rooms quickly and without major disruption to operations. Banks must serve their customers personally and confidentially. There are opportunities here to optimize the business without any construction effort. Consultant rooms no longer necessarily have to be located on the facade or wall. Room-forming walls do not have to be pulled up to the ceiling, which is often designed, in order to be laboriously connected there. Free-standing room systems can be distributed in the checkout hall as necessary in order to offer the necessary services directly at the point of sale.

Manufacturing - rooms for shop floor management

Shop floor management strives for permanent improvements and optimization of processes directly at the place where things happen, “on the hall floor”, in the workshop. But shop floor management is even more. Not only the processes directly on the shop floor should be optimized, but also the management and management tasks and the associated work culture. This is accompanied by an increased appreciation of the value-adding level and a shift in decision-making authority to this level. In order to achieve these goals, it is absolutely necessary to communicate with the affected players on site, regularly, for a limited time and intensively. In the noisy environment of a production facility, acoustically quiet retreat spaces with appropriate media equipment are required. With a sound insulation of 37 dB or alternatively 40 dB, vetroCUBE acoustically isolates retreat areas in production, thus offering the best sound insulation. The system also offers good room acoustics in the interior, even for team rooms. Compared to the classic master cabins, the modern and delicate design of the vetroCUBE offers the great advantage that visual connections are maintained. Employees remain within sight and in close proximity to the processes. There were also representative advantages for high-tech manufacturing. Last not least is available Vetrocube in every size and in every equipment and thus meets your individual demands on the Shop Floor.

Why room in room?

From the user's perspective

Because success requires a change between communication and concentration. Managers are increasingly becoming convinced that employees should communicate in teams and as often as possible. It goes without saying that colleagues are now constantly accessible. Systems like Skype and similar ones put the employee on “permanent online”. But a study shows limitations. A large-scale experiment provided proof. Scientists had 600 small groups solve tasks in three different situations. Situation 1: the team members had no contact with each other at all. Situation 2: the team members had contact with each other after each round and were able to exchange results. Situation 3: the team members had contact with each other after every THIRD round. The scientists' expectation was that situation 2, i.e. the teams constantly communicating, would produce the best results. This expectation was not confirmed! Situation 3, the alternation between communication and concentration, brought the best solutions. Only communication at intervals improves the results of low performers as well as those of high performers. Insight into the work of your teammates is important, but so is having enough time to reflect on this information in a concentrated manner.

Source: Ethan Bernstein et al.: "How Intermittent Breaks in Interaction Improve Collective Intelligence", Proceedings of the National Academy of Sciences, August 2018.

Let’s build a bridge to open office spaces. One would think that communication is not neglected here. But is it really happening? Colleagues quickly feel disturbed and conversations have to take place in whisper mode and are therefore often avoided. The supposed communication ability of the open office brings the opposite result. It is important that the area offers retreat areas and in sufficient numbers. Room-in-room systems are the appropriate means of choice here. In the immediate vicinity of the workplace, clearly visible, easy to see and therefore without complex booking scenarios, the think tanks offer the necessary retreat areas for teamwork, conferences, telephony or simply maximum concentration. Creating spatial diversity: room-in-room, back bone of new work!

From a facility management perspective

It sounded a little higher up. The room-in-room system from woodtec makes rooms possible where conventional constructions, floor-to-ceiling partition walls, cannot offer a solution. Consider your midzone. It is rare to find the opportunity to ventilate trapped rooms. For this reason, partition walls are out of the question. But even if ventilation were possible here, the FM is well advised to rely on room-in-room solutions. Compare the installation of a partition wall with the installation of a room-in-room construction.

The installation of a partition wall system requires many specialist companies:

- Partition builder

- Ceiling builder or drywall builder (ceiling bulkhead for comparable sound insulation)

- Electrician (laying lights, changing circuits)

- Ventilation engineer (bring in ventilation pipes, if at all possible)

- Facility management or external architect (coordination of work)

- Fire protection (smoke detectors, signaling devices, sprinklers)

The installation of the room-in-room construction vetroCUBE, on the other hand, only:

- the woodtec assembly team

- Fire protection (if required)

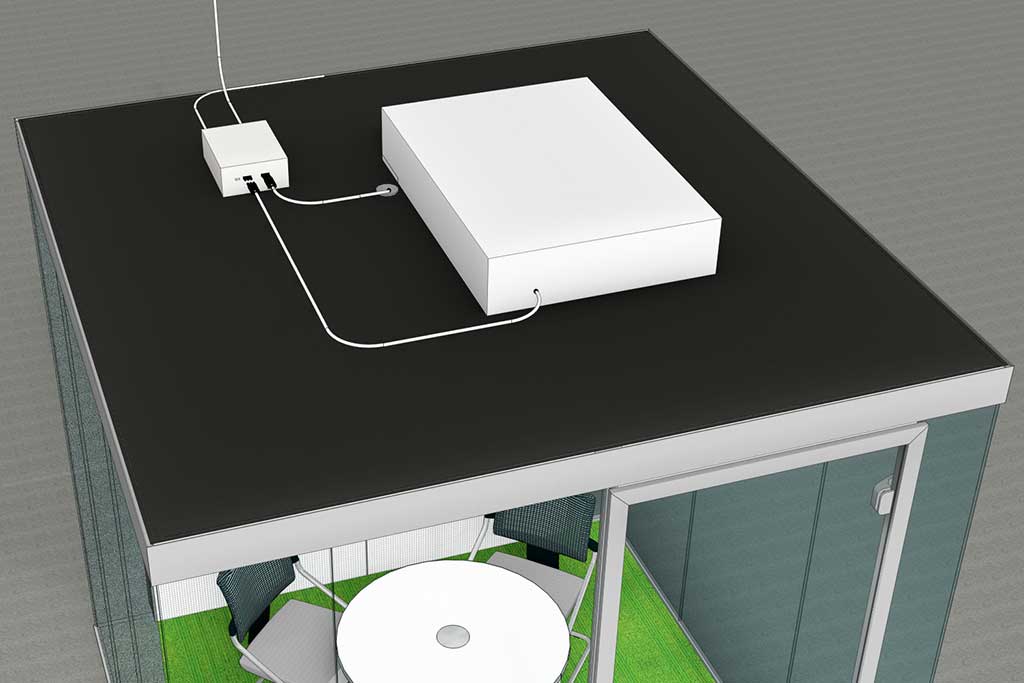

The same applies to the renovation, which, based on experience, takes place faster and more often than expected. The free-standing room solutions can be set up and moved quickly without an engineering package. The answers, from the FM perspective, are: independence for planning, flexibility, versatility, adaptability and sound insulation. The cube is self-sufficient. It is independent of the building. This brings enormous advantages to the area planner and facility management. The room-in-room system does not require a connection to the facade or wall. The cube can easily be positioned freely on the surface and operated using the “plug and play” method. The retreat space is already working. It also does not need a connection to the building's ventilation system. These space constructions are self-ventilating. They do not rely on the building's lighting and provide their own internal electrification. The system is easy to assemble and disassemble again. There are no dismantling costs. The room-in-room systems can be easily relocated spatially. They can be moved with you and are reusable. The investment remains intact. Decoupling from the building offers tax and financial advantages.

From a controlling perspective:

Room-in-room units are located on 2b areas, beyond the facade. The premium area on the facade remains free of conference rooms and is therefore fully available for workspaces, the “work space / multispace”. The vetroCUBE spatial construction significantly optimizes the area metrics.

From a controlling perspective:

vetroCUBE supports customers in consolidating office space. Room-in-room units are located on 2b areas, beyond the facade. The premium area on the facade remains free of conference rooms and is therefore fully available for workspaces, the “work space / multispace”. The vetroCUBE spatial construction significantly optimizes the area metrics. Employees still like to use the office at home to work from there one to three days a week. Working from home, but also other periods of absence, lead to vacancies in the office. The employer is required to react. On the one hand, empty office space is in no way economical, but on the other hand, partially occupied space is not very conducive to communication and creativity. The employees who are in the house should at least sit together and be able to interact with each other as easily as possible. The agile office has solutions ready. Workstations are no longer assigned personally but can now be booked.

The middle zone is used for communication. Areas on the facade are largely reserved for workplaces. The office space will be open plan. A variety of spatially and acoustically different zones offer specialized workplace areas that employees can access “on demand”. This creates retreat areas that ensure that employees, once they are in the house, can work together communicatively and creatively. This intensive use of newly designed areas makes other areas completely free. The entrepreneur can decide whether to shut them down and keep them in reserve or to market them.

With sustainability in mind:

What is crucial is the endless reusability of the room-in-room system. As previously described, no waste is created when rescheduling or moving. The materials or components are reused 1:1. Things look completely different when partition walls are used. Drywall solutions in particular must be completely torn down and disposed of. Due to the height of the room, system walls can rarely be used again. In addition, the woodtec room-in-room system is manufactured from a sustainable perspective. The product will soon be CO2 neutral. All materials consist largely of recycled materials or are recyclable. Packaging is reused.

How much does space cost in space?

A retreat room in room-in-room construction, e.g. for meetings for 4 people, floor area approx. 7.3 m², as you can find it on the "Solutions" page in "Line 3", under the name Type C.2, costs approx. 14,000.00 euros. This guide price already includes delivery and assembly on the German mainland. The room in room system is then fully equipped. with the system-integrated ventilation, with the dimmable LED lighting, with the complete electrification and the intelligent control via touchscreen. The price applies to the standard version, i.e. silver-colored profiles, white surfaces, three sides with frameless glazing, one side with a solid wall and the support-free glass corners.

vetroCUBE technology and functions:

Self-supporting construction:The system stands freely on the surface. The space construction is self-contained and self-supporting. The stability and stability have been statically proven. If desired, the unit can be supplied with its own floor. The system-compatible floor then completely decouples the system from the building. The vetroCUBE no longer needs to be screwed into the floor of the building. The ground also offers additional potential for electrification.

Modular principle:

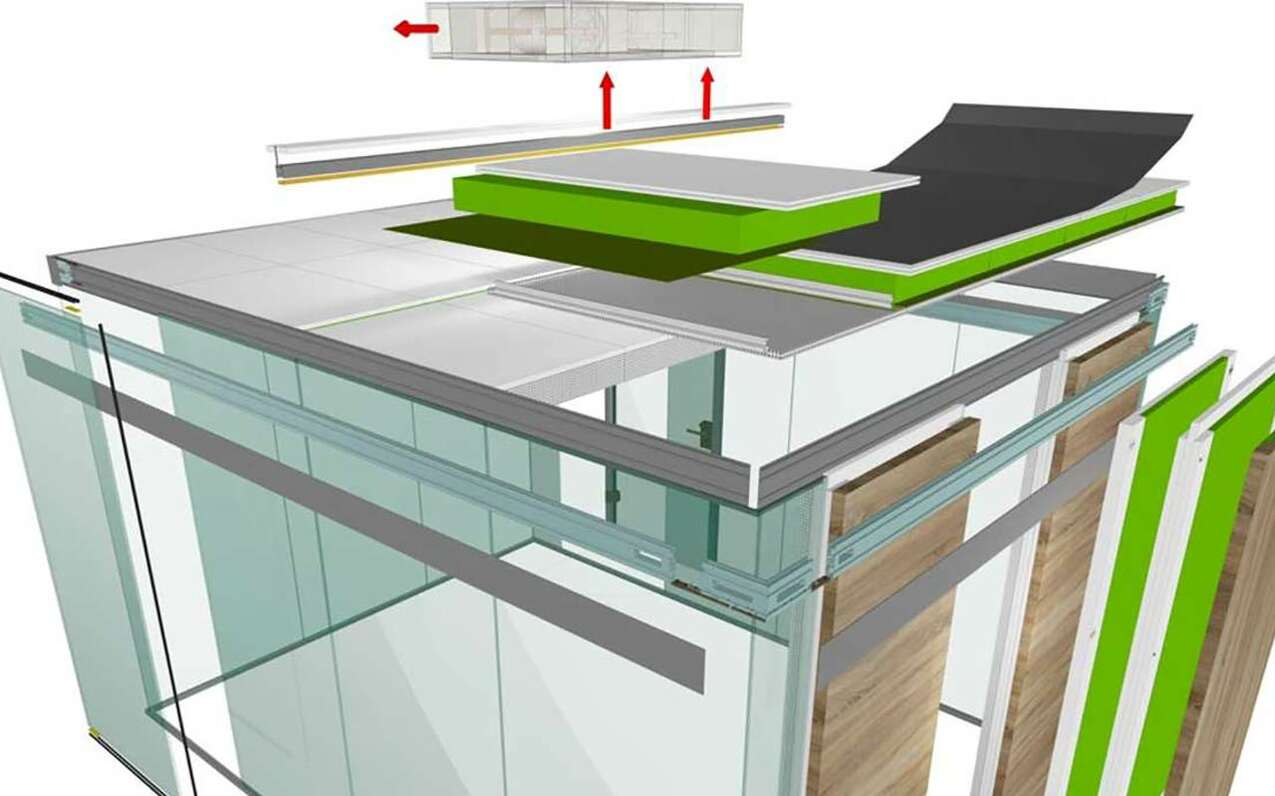

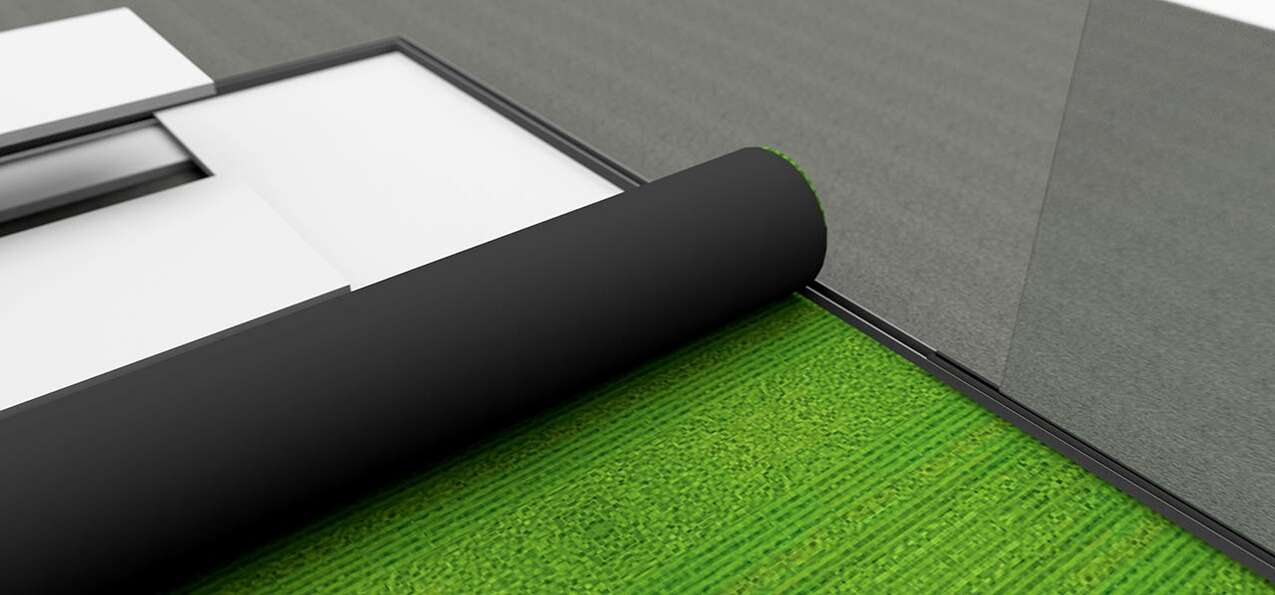

vetroCUBE is a modular system for room-in-room. A floor ring and a ceiling ring made of aluminum profiles, as well as load-bearing walls form the basic framework. All aluminum profiles are anodized silver (EV1). The walls are frameless all-glass elements or solid wall elements.

The glass-only elements are 12 or 16 mm thick and are designed as LSG sound insulation elements. The solid wall elements are a 3-layer sandwich construction, consisting of a central support element and a functional panel on the inside and outside. These functions can be whiteboard, high-performance absorber or simple decoration. The solid walls are not a product of conventional partition systems, but are specifically designed for the purpose of the vetroCUBE. The doors are all-glass doors, 12 mm ESG or solid doors. They are room-high and equipped with lowerable floor seals. The frame is a delicate aluminum profile. The fittings are made of stainless steel and meet the highest standards. The ceiling is a construction made of load-bearing profiles and invisibly fastened metal cassettes. The ceiling is micro-perforated and has a complex structure made up of material components that, on the one hand, ensure a high level of sound insulation, but also ensure optimal room acoustics in the vetroCUBE. The modular structure of the room systems enables the provision of a wide variety of room units. This refers to the size, as well as the features or transparency.

Accessibility and OPTION base plate:

Every now and then we receive a request to assemble room-in-room constructions WITHOUT any attachment to the structure, i.e. H. even without drilling holes in the ground. On the one hand, we would like to point out at this point that direct attachment to the floor enables a ground-level entrance and thus ensures accessibility. On the other hand, it is simply common for spatial structures to have to be attached to the ground, so this requirement usually goes hand in hand with special locations. Often it is high-quality stone floors, for example in a lobby, that need to be protected. The landlord's demands and the associated dismantling costs are rarely the reason for this request. In order to be able to react to this situation, we offer a system floor for the vetroCUBE. The construction of the vetroCUBE is built on this composite floor in the usual way, so that it then forms a self-contained unit. The screws are screwed into the system base and this provides sufficient support for all other components. The floor also offers cavities for feeding the electrification into the wall elements. As is always the case, this solution also has a disadvantage. A 50 mm high threshold is created for the user in the entrance area. The advantage is that the floor inside the vetroCUBE can be designed as desired.

Room-in-room units in chaining:

It is not uncommon for these spatial concepts to be planned in blocks. To link the vetroCUBE units, it is necessary to decouple the systems acoustically. A simple solution with a central wall would result in excessive sound transmission. Experience shows that the simple wall is very good for soundproofing towards the busy office space, but not optimal for ensuring confidentiality between quiet rooms. So we place two independent think tanks next to each other, link them visually, but keep them acoustically decoupled. The user can separate the rooms at any time and set them up separately. Conversely, he can combine the rooms at any time.

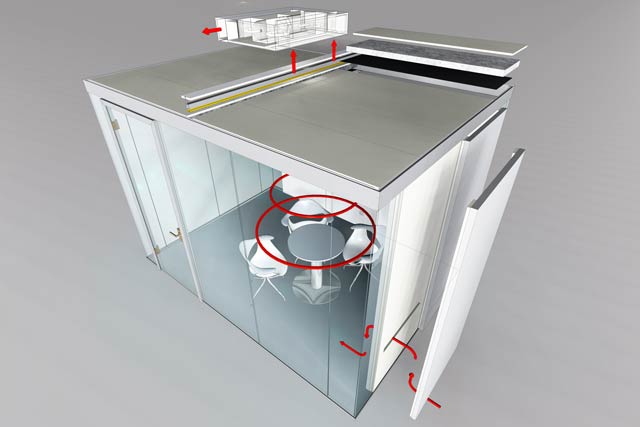

Integrated system ventilation:

The basic prerequisite for the independent function and acceptance of the vetroCUBE, even beyond the façade, is the quiet and powerful integrated ventilation system. The fan box, the active component of the ventilation system, is located on the ceiling element above the luminaire. Heated and "stale" air is extracted via the ceiling light. Fresh air is supplied via passive air vents in the solid wall elements. The sandwich structure of the solid wall enables good sound insulation of the air inlet openings and thus offers advantages over a mullion and transom construction. At the same time, theair vents close to the floor draw on the coldest layer of air in the surrounding room. In this way, the ventilation concept helps the vetroCUBE to heat up much more slowly. The ventilation concept works in harmony with the natural thermal system. With a control air flow rate (volume flow) of 370 m³/h, the fan box emits only approx. 30 dB(A) and thus supplies 6 people. The volume flow, the control air flow rate, is adapted to the size and occupant capacity of the room-in-room unit. This is achieved on the one hand by adjusting the fan speed, but also by the number of fan boxes fitted.

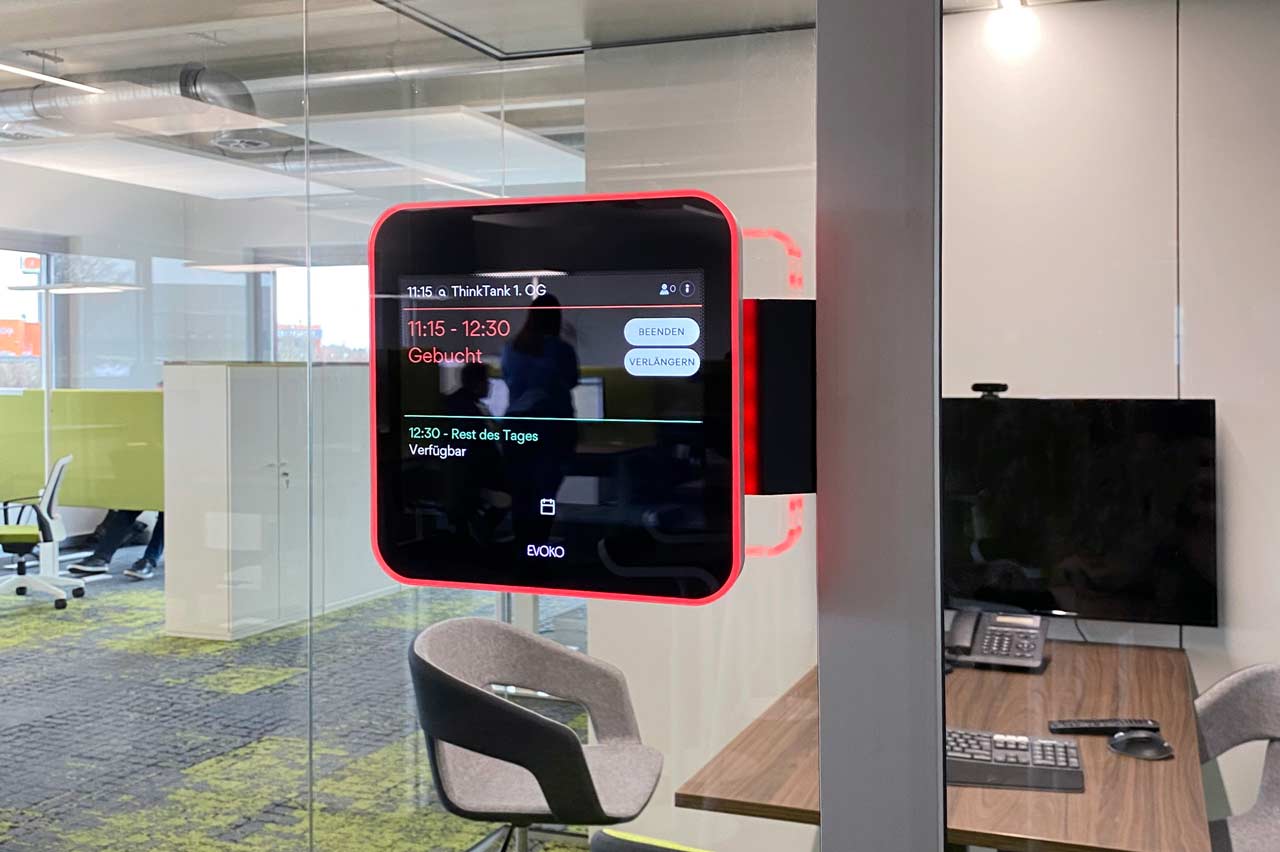

Control of the ventilation system

A presence detector in the ceiling switches the ventilation automatically. As soon as the user enters the cube, the ventilation is activated with an output of. at least 60 m³/h and person (depending on the capacity or size of the cube) switched on. This volume flow ensures a very good supply. The user will find a TFT screen next to the door. The user can adjust the settings using this touchscreen. The air output can e.g. can be increased to 600 m³/h for a short time, but falls back to the preset performance after 5 minutes in order to run as quietly as possible. Nevertheless, this “air shower” can be helpful. If the user leaves the cube, the ventilation continues for approx. 5 minutes and then switches to “stand by”. The next user will then find the room-in-room unit back in its default settings. The basic setting parameters can be adjusted at the facility management level. To do this, you must enter a PIN. For example, the “Keep Fresh” function can be activated here. Stand-by operation now delivers a minimum amount (approx. 50 m³/h) to “keep the think tank fresh”. At night, e.g. B. between 10:00 p.m. and 6:00 a.m. the ventilation switches off completely. All parameters can be changed individually on this FM level.

Freedom from maintenance:

The ventilation system is maintenance-free. In the basic configuration there are no air filters or other components that need to be replaced or maintained. After all, the air has the same quality as that which our colleagues breathe in the open space, so filters, for example, are obsolete. However, filters can be installed if desired. The fan box is prepared for this.

Option for connection to the on-site ventilation system:

If the building can offer on-site ventilation at the planned parking spaces, it is also possible to connect the Think Tank to the building's own ventilation system. Supply air pipes can be connected via appropriate cutouts in the system ceiling. The exhaust air can be passively diverted via the previously described overflow openings in the solid walls. This variant makes particular sense if there is a need to supply the room with fresh, filtered and possibly cooled air.

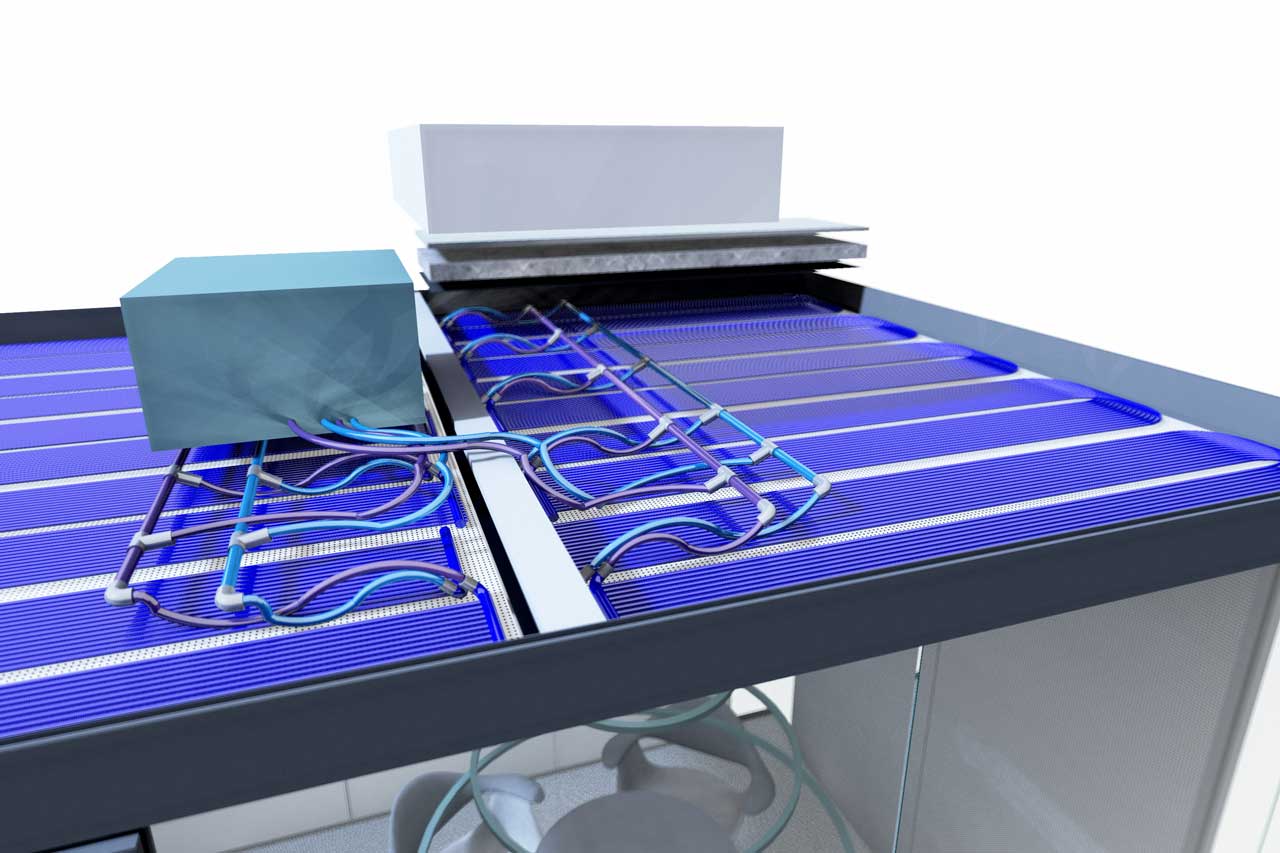

Cooling:

The room-in-room system often forms very compact room units. 7-9 m² of floor space often has to be enough to provide a meeting room for 4 people, for example. Experience shows that the good feeling of space often leads to long periods of use. Now you have to keep in mind that each user contributes a heating output of approx. 100 W, so that, depending on the ambient temperature in the large area, undesirable heat loads can occur. For such cases, vetroCUBE offers comfortable cooling, a cooling ceiling. We consciously decided against circulating air cooling. This would lead to drafts, especially in small rooms.

The vetroCUBE ceilings consist of micro-perforated metal cassettes. These metal cassettes become cooling elements in which heat exchangers (cold water meanders / pipe coils) are attached to the back. The cooling ceiling equipped in this way is now connected to a closed cold water circuit. This can be an on-site cold water route or a self-sufficient dry cooler, which in turn stands as a box on the ceiling element. The cool surfaces now absorb the existing heat loads. The system is extremely convenient. We consciously decided to separate the cooling from the ventilation (separation system). This offers the advantage of being able to optimize the ventilation solely to relieve the material load on the air and to optimize the cooling to relieve the thermal load.

Sound insulation / sound insulation:

With certified sound insulation of 37 dB or 40 dB, the room-in-room solution reliably seals off confidential conversations. At this point, remember that the ambient noise has a decisive influence. The sound insulation of the room-in-room system optimizes the room acoustics and thus the efficiency of the office space. The certificate / certificate refers to the entire construction. Please do not allow yourself to be blinded by higher values for individual components at this point. Ultimately, the weakest assembly is the limiting factor. Particular attention should be paid to the construction of the ceiling. The functions of ventilation, sound absorption and sound insulation must be brought together here. vetroCUBE therefore relies on a relatively high ceiling height of 130 mm and deliberately does not integrate the fan into the ceiling element, but rather places it on top in order not to weaken the important functions mentioned above.

Room acoustics, reverberation time:

The acoustic quality inside the thinker's cell, the reverberation time, must be adjustable. Basically, the ceiling of the vetroCUBE is acoustically highly effective, i.e. designed as an A-class absorber. The high acoustic value of this micro-perforated metal cassette ceiling ensures that the reverberation time is between 3 and 4 s, i.e. optimal room acoustics is achieved. This applies to all rooms larger than or equal to 6 m². The main advantage of ceiling absorption is that solid wall surfaces do not have to be equipped with wall absorbers. This means that solid walls can be minimized to create a light feeling of space or can be used for other functions (whiteboard / projection surface / screen / decoration). Only particularly small rooms, smaller than 6 m², should also be equipped with wall absorbers. These absorbers are also micro-perforated metal cassettes and are A-class absorbers. With these elements, even very small rooms (telephone booths smaller than 2 m²) can be acoustically optimally conditioned. The reverberation time can be adjusted precisely so that even sensitive hands-free devices work well. All absorbers from woodtec are equipped with a polyester fleece. This material is a recycled product made from PET bottles and is itself recyclable. It also bears the Ökotex seal and is therefore beyond any ecological and ergonomic doubt. The acoustic material has been tested and meets all human ecological requirements according to Standard 100 OEKO-TEX.

Light:

Room solutions need good lighting, individually dimmable and intelligently controlled. The number of lights depends on the size of the vetroCUBE. Appropriate lighting calculations ensure that a professional lighting situation is provided. The light is switched on and off via a presence detector integrated in the ceiling. In addition, the user has the option of switching or dimming the light individually, e.g. to adapt the lighting conditions to a screen presentation.

Electrification:

Ready-to-use and pluggable electrification is just as important. The room-in-room solution is manufactured and provided according to the “plug and play” principle. All electrical elements installed in the cube are fully wired internally (pluggable and reverse polarity-protected connections). For 230V electrification, all functions come together in a control box on the ceiling element. Here we offer an interface, a Wieland GST18i3FS2RV socket, for the mains connection. A cable with the appropriate plug must be provided on site. During installation, we connect the vetroCUBE using a test cable and check all functions. The local electrician must be responsible for the formal commissioning in accordance with DIN VDE 0100. For the data electrification, the responsible service provider hands over the appropriate cables to us so that we can pull them into the full walls of the vetroCUBE to the prepared slots during installation.

In the room-in-room system, we offer interfaces after consultation with the customer. Standard equipment includes 3 230 V sockets and 2 RJ 45 interfaces. On request, we can also offer HDMI, VGA or USB interfaces.

Interface to building management technology

On request, we realize an interface to the building management technology for the room-in-area system. In this case, we connect the control of the room-in-area unit to a specially developed gateway. This gateway is connected to the building management technology via a Modbus protocol. The building management system then has the option of controlling the vetroCUBE and/or reading out status information from the room-in-room unit. Optionally, an additional TFT screen can be connected to the control to display booking information from a superordinate system. You can obtain precise information on the readable or displayable information in a tabular form on request. Just talk to us.

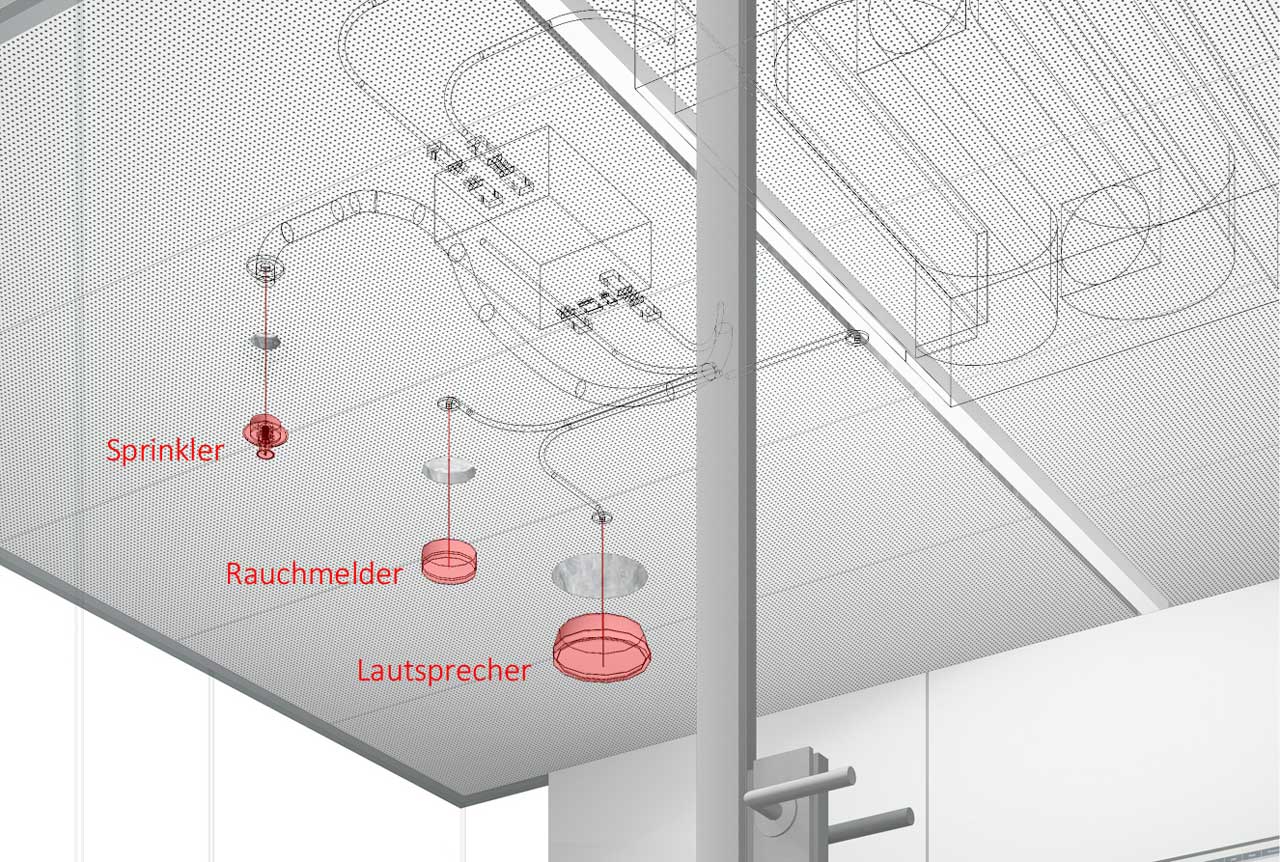

Fire protection:

The room-in-room system is self-supporting and self-sufficient. This core statement about the system is correct and yet there are dependencies that make interfaces to the building necessary. With electrification we have become acquainted with an interface. Further connections to the building result from the needs of fire protection. If an office space has to be equipped with a fire alarm system, experience shows that this applies to every room. Then such a system must also be installed in the room-in-room units. Smoke detectors must also be installed there and, depending on requirements, connected to the fire alarm system. The same applies to ELA systems. Depending on the fire protection concept, these loudspeakers must also be able to be installed in the room-in-room system. A comprehensive sprinkler system can also be part of the fire protection concept. If this is the case, the sprinkler head must also be able to be installed in the room-in-room system.

It is not uncommon for us to receive requests for non-flammable room-in-room units. These are often rooms that have to be set up in foyers or similar areas, for example. The fire load may not be increased on such areas. In this case, we can design the room-in-room system in non-combustible quality, in A1 quality.

Consideration of the drywall alternative

At this point, we strongly recommend that you reflect on the original train of thought that initiated the development of room-in-room systems. The system should be able to create rooms that are decoupled from the building, it should be as easy to install as furniture, easy to move and therefore adaptable to the flexible needs of the open space at any time. We recommend thoroughly evaluating how important dust-free assembly and moving or relocatability are. Think about your ongoing operations. The reusability of all components must be assessed just as much as the modular expandability of the vetroCUBE. Think about the acoustics in the room and the ready-to-use electrification of the vetroCUBE. Compare these properties with those of a plasterboard construction.

We believe that evaluating the design is particularly important. Imagine the vetroCUBE with three-sided glazing in an open space and mentally place the drywall construction, consisting of Rigips panels and UA profiles, next to it. Now assess the impact on the architecture of the open space.